What is a VMC machine used for?

What is a VMC Machine Used For?

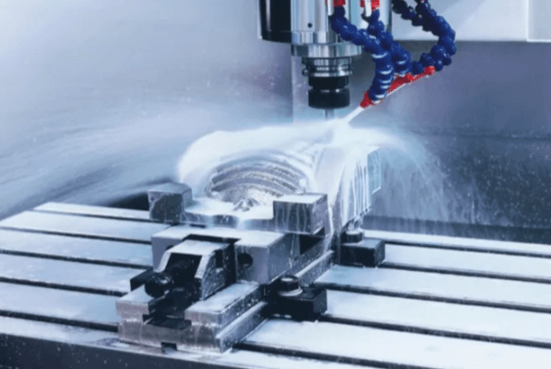

Vertical Machining Centers (VMCs) are pivotal in modern manufacturing environments, offering precision and versatility for a variety of applications. This guide will explore the numerous uses, benefits, and types of VMC machines, alongside their integral role across different industries.

Introduction to VMC Machines

A Vertical Machining Center (VMC) is a type of CNC (Computer Numerical Control) machine that allows for precise cutting, drilling, and milling of materials. It features a vertically oriented spindle that moves vertically to reach the material, making it ideal for creating complex shapes and surfaces with high accuracy.

Brief History of VMC Machines

The evolution of VMC machines dates back to the post-World War II era when the demand for faster and more precise manufacturing processes led to the development of CNC technology. VMCs were among the first machines to adopt this technology, revolutionizing the manufacturing landscape.

Components of a VMC Machine

The spindle is the heart of any VMC machine, responsible for holding and rotating the cutting tools at high speeds. It’s critical for achieving the precision that VMCs are known for.

The control panel serves as the interface between the machine operator and the VMC itself, equipped with sophisticated software that interprets CAD/CAM files and controls the machine’s movements.

A tool changer automates the process of switching between different tools during a job, enhancing the machine’s efficiency and reducing manual labor.

Primary Applications of VMC Machines

In the automotive sector, VMCs are used for everything from prototyping new parts to full-scale production, helping to create complex components like engine blocks and chassis parts with high precision.

The aerospace industry relies on VMC machines for the production of aircraft components that require stringent tolerances and superior materials, such as titanium and advanced composites.

Contributions to the Electronics Industry

VMCs help in the manufacture of intricate electronic components, including PCBs (Printed Circuit Boards) and enclosures, ensuring precision and consistency critical to the electronics industry.Machines

The precision of VMCs is unparalleled, making them indispensable in industries where a fraction of a millimeter can be critical.

VMCs streamline production processes, allowing for continuous operation and reduced human intervention, which translates into higher throughput.

With capabilities to perform a variety of machining tasks on a single machine, VMCs are extremely versatile and valuable in complex production setups.

Cost-Effectiveness Over Time

Although the initial investment may be high, the long-term savings due to reduced labor costs and increased efficiency make VMC machines a cost-effective choice.

Setting Up a VMC Machine

Setting up a VMC involves ensuring adequate space, stable power supply, and environmental controls to maintain machine accuracy.

It’s critical to adhere to safety protocols to protect operators from the high-speed operations of the machine. Regular training and adherence to safety guidelines are imperative.

Operators must undergo specific training to manage sophisticated VMC machinery effectively, focusing on both technical skills and safety practices.

Innovations in VMC Machine Technology

Recent advancements include integration of IoT (Internet of Things) for better machine monitoring and predictive maintenance, and the use of AI to optimize machining processes.

Automation and AI enhance the capabilities of VMCs by improving precision, reducing waste, and increasing production rates without sacrificing quality.

Emerging trends include the development of more energy-efficient models and further integration of smart technologies to facilitate autonomous operations.

Comparing VMC with Other CNC Machinery

While VMCs excel in making precise vertical cuts, horizontal milling machines are preferred for heavy-duty cuts and handling larger pieces.

CNC lathes are optimized for cylindrical parts and operate differently from VMCs, which are more versatile and capable of handling a variety of shapes and sizes.

Deciding between a VMC and other CNC machines involves considering the specific requirements of your projects and the materials you’ll be working with.

Maintenance and Troubleshooting VMC Machines

Regular maintenance is crucial for extending the life of a VMC, involving periodic checks and replacements of critical components.

Operators should be familiar with common mechanical issues, such as tool misalignment or software glitches, and know how to address them quickly.

With proper maintenance, a VMC can have a long operational life, often surpassing decades of use.

Real-world Examples of VMC Machine Applications

Successful case studies often showcase significant improvements in production speed and reduction in material waste, proving the effectiveness of VMC machines in modern manufacturing.

Examples from industries such as automotive and aerospace demonstrate how VMCs have been instrumental in developing innovative products and solutions.

Impact on Product Quality and Consistency

The precision and repeatability of VMCs ensure that products meet stringent quality standards, which is especially crucial in high-stakes industries like aerospace and medical devices.

FAQs About VMC Machines

- What is the cost of a typical VMC machine?

- The cost can vary widely depending on the size, functionality, and technology incorporated, ranging from tens of thousands to hundreds of thousands of dollars.

- How to choose the right VMC machine for your business?

- Consider the types of materials you’ll be machining, the complexity of the parts, production volume, and your budget.

- What training is required to operate a VMC machine?

- Operators need specific training on CNC programming, machine operation, and maintenance, often provided by the manufacturer or specialized training centers.

Conclusion

VMC machines represent a significant investment in manufacturing technology, offering substantial benefits in terms of efficiency, precision, and flexibility. As technology continues to advance, the capabilities of VMC machines will expand, further enhancing their role in modern manufacturing.